INTRODUCE

Company Introduction

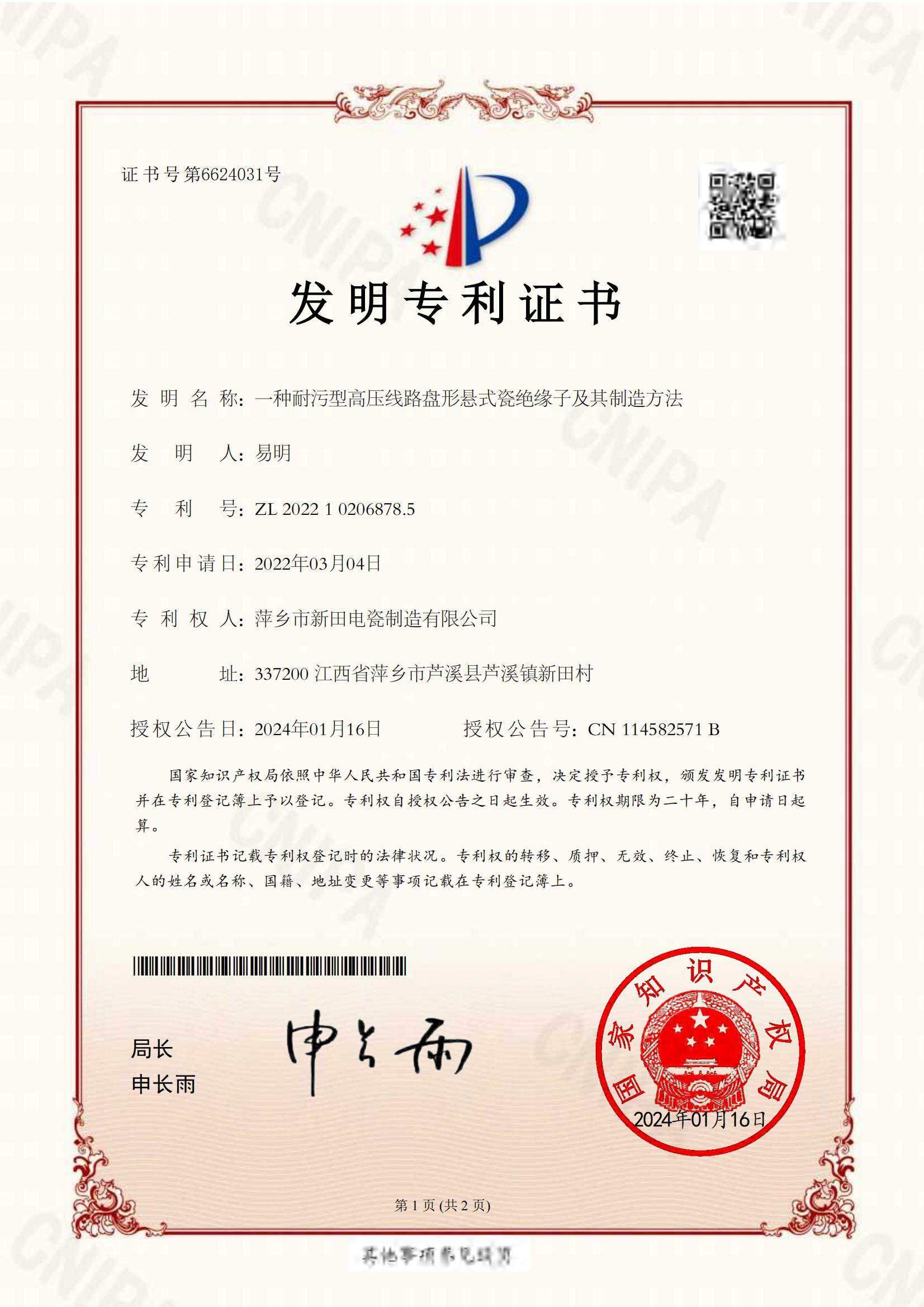

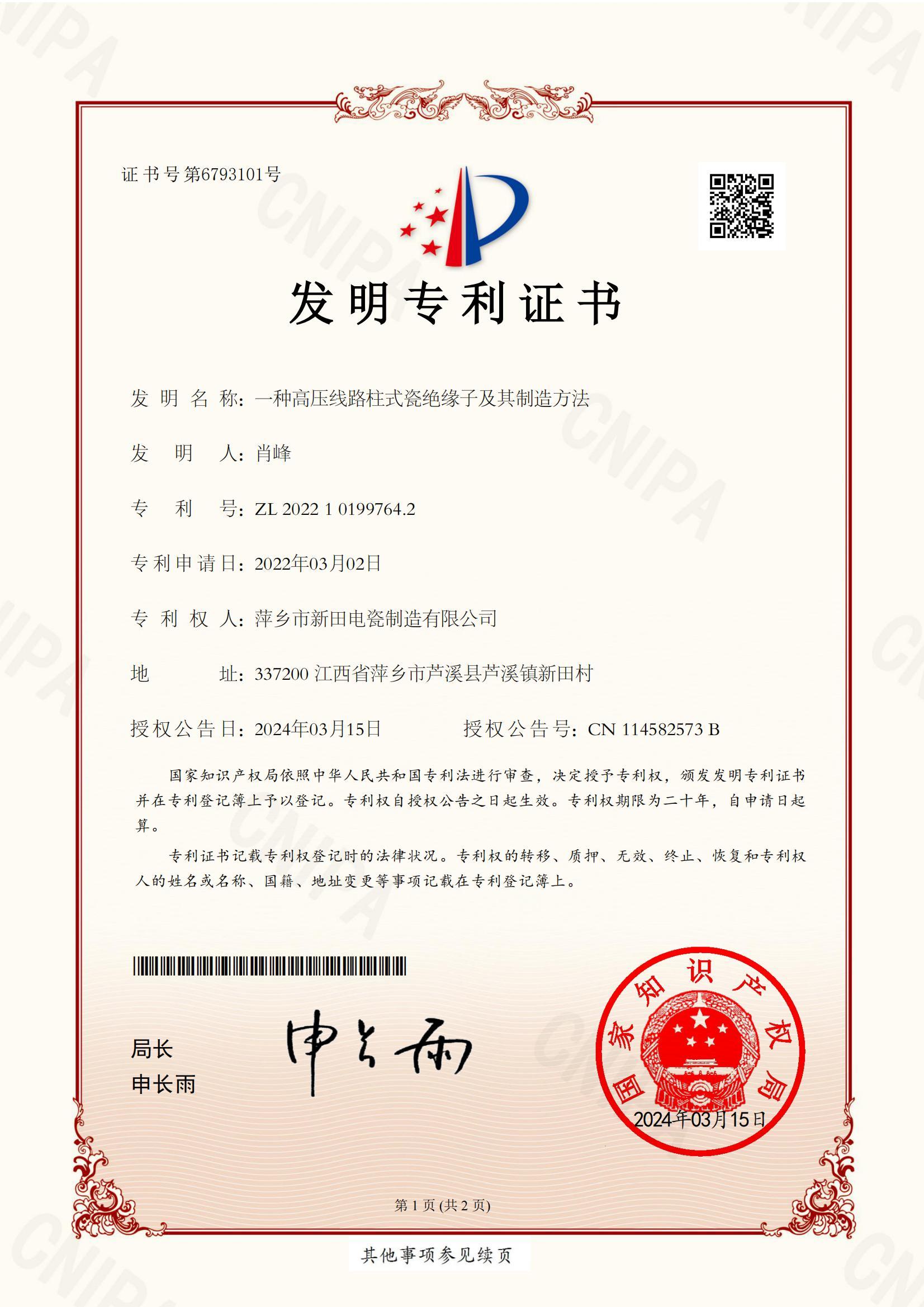

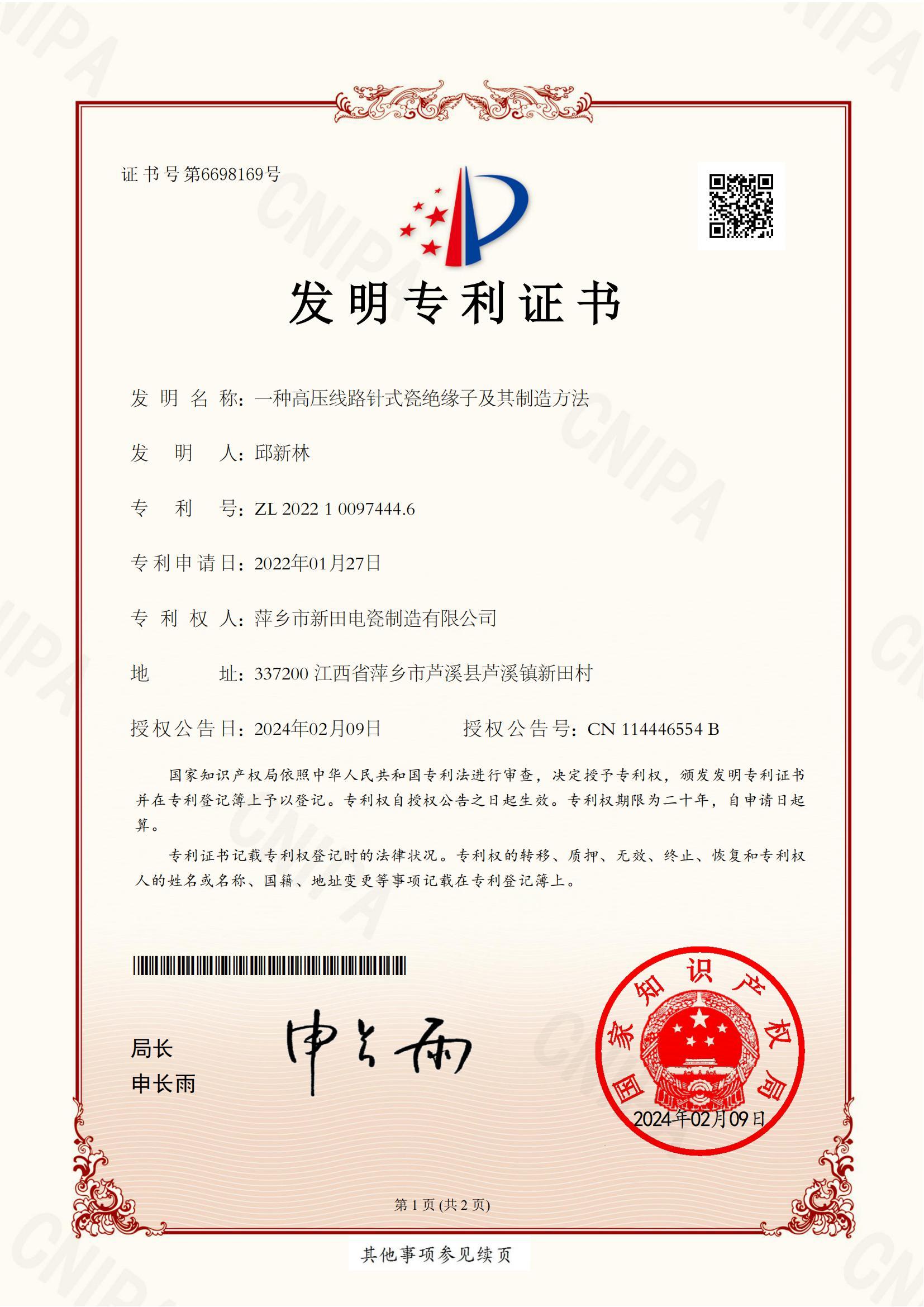

Pingxiang Xintian Electric Porcelain Manufacturing Co., Ltd was established in 1997, located at the western gateway of Jiangxi Province, Pingxiang City. It currently has more than 130 employees, including 17 senior and intermediate engineers. Since its establishment, the company has been rooted in the research and production of high-voltage line porcelain insulators and composite insulators. After nearly thirty years of dedicated work, the company has developed into an industry pioneer integrating national high-tech enterprise, specialized and innovative enterprise, digital intelligent manufacturing benchmark, and green factory. Innovation is in our genes. We have obtained more than thirty national patents, including 9 invention patents, 28 utility model patents, and 10 software copyrights, building a solid technological barrier. These core achievements support our power grid performance covering every province in the country and have successfully exported to multiple countries including Egypt and Bangladesh. Currently, the company’s annual output reaches more than 2 million pieces, with 2 industry-leading fully automated digital production lines for suspended and post-type porcelain insulators. "Unity and progress, pragmatic effectiveness, honesty and trustworthiness, quality first" is the corporate spirit deeply ingrained in Xintian Electric Porcelain people. We craft every product with a craftsman’s heart, striving for technical excellence and meticulous quality.

The company firmly remembers its mission to ensure the reliability of power grid supply. All products have established a full traceability mechanism from raw materials, production processes, semi-finished products, finished products to shipment, practicing the quality-first spirit of Xintian Electric Porcelain with practical control measures. The products have successively passed quality inspections and certifications by national authoritative institutions such as the Power Industry Electric Equipment and Instrument Quality Inspection and Testing Center (Beijing), National High Voltage Electrical Apparatus Quality Supervision and Inspection Center (Xi’an), Power Industry Electrical Equipment Quality Inspection and Testing Center (Wuhan), National Electrical Product Quality Supervision and Inspection Center (Jiangsu), and National Ceramic Product Quality Supervision and Inspection Center (Jiangxi). The company has a complete and mature operation management system and has passed ISO 9001:2015 Quality Management, ISO 14001:2015 Environmental Management, ISO 45001:2018 Occupational Health and Safety Management system certifications.

Pingxiang Xintian Electric Porcelain Manufacturing Co., Ltd is driving development through innovation, leading the future with intelligent manufacturing, practicing responsibility with green initiatives, continuously contributing professional strength and intelligent solutions from China’s core electric porcelain production area to the safe, efficient, and stable transmission of global electric power energy.

Our Vision

To become the Chinese benchmark in the global power safety protection field,

Lighting a sustainable energy future with insulation technology.

PRODUCT

Product Center

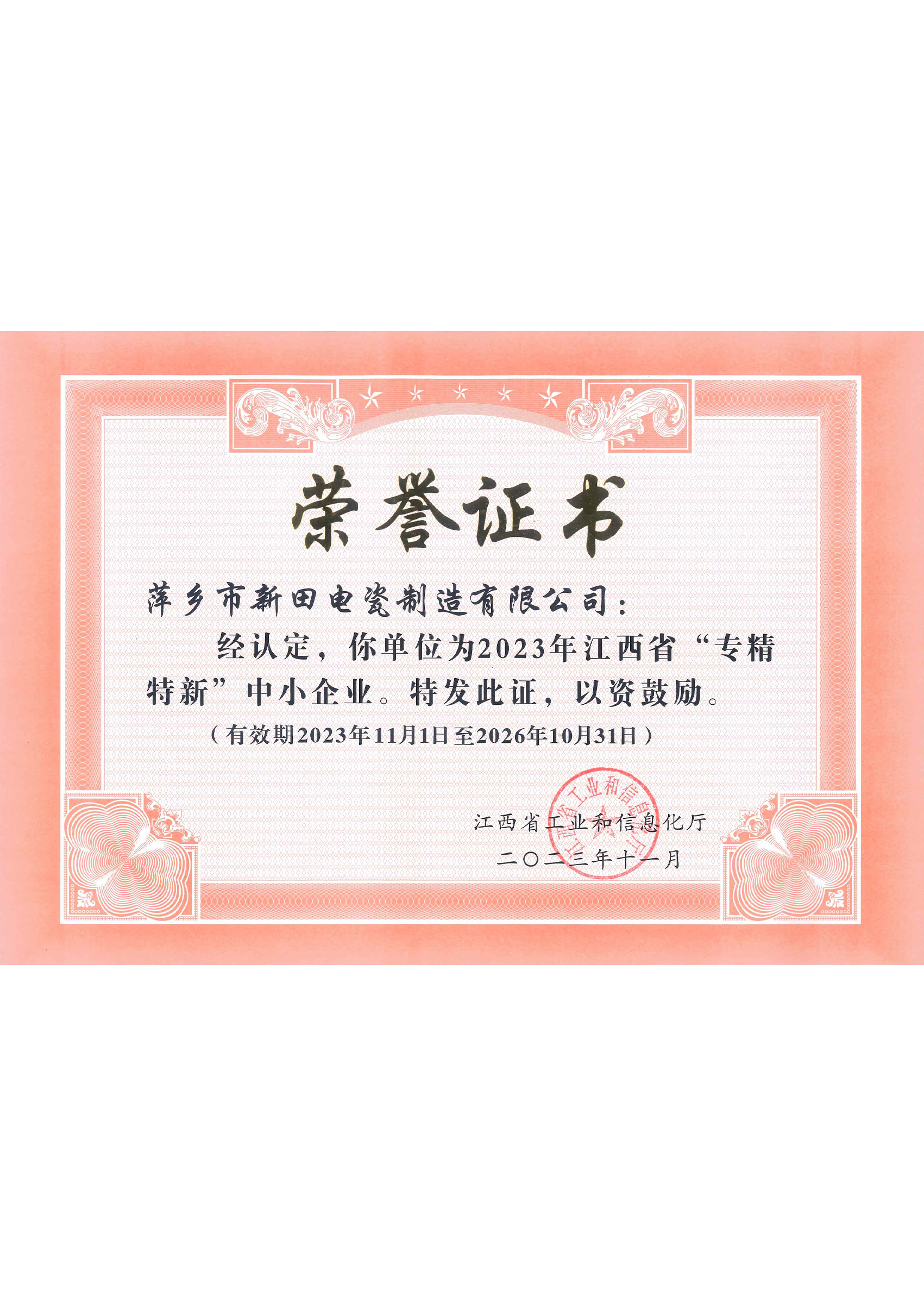

Honor

Honor and Qualification

NEWS

News and Information

Where are butterfly insulators generally installed?

2025-08-18

Pin Insulators and Post Insulators: Differences and Applications

2025-08-18

Requirements for Installing Suspension Insulators

2025-08-18

Principle of High Voltage Line Insulator Structure

2025-08-18

PARTNER

Partners

Leading the future, we have accumulated a wealth of experience

Leading the future with intelligent manufacturing, practicing responsibility with green initiatives

Learn More >>